Sunscreen fabrics such as mesh fabrics for sunscreen roller blinds and zebra roller blinds are generally used to prevent sunlight and glare caused by these rays. In addition to providing sun protection properties, sun protection fabric curtains must generally be flame retardant (have flame retardant properties), and must have sufficient rigidity to properly hang on a window or other structure using the window, and in many cases , Can resist the role of light.

To achieve these goals, sunscreen roller blinds are usually made of a fabric woven with vinyl-coated glass fiber or polyester yarn, which is then calendered. While providing a certain degree of sun protection filtering, these existing materials are limited in terms of aesthetics. On the one hand, since the PVC coating is opaque, the color of the shadow is determined by the color of the vinyl coating of the yarn, so the available palette is usually limited. In addition, the construction of sun roller blinds is limited to conventional open weave patterns. In addition, the PVC coating must be sufficient to prevent the edges of the braid from fraying.

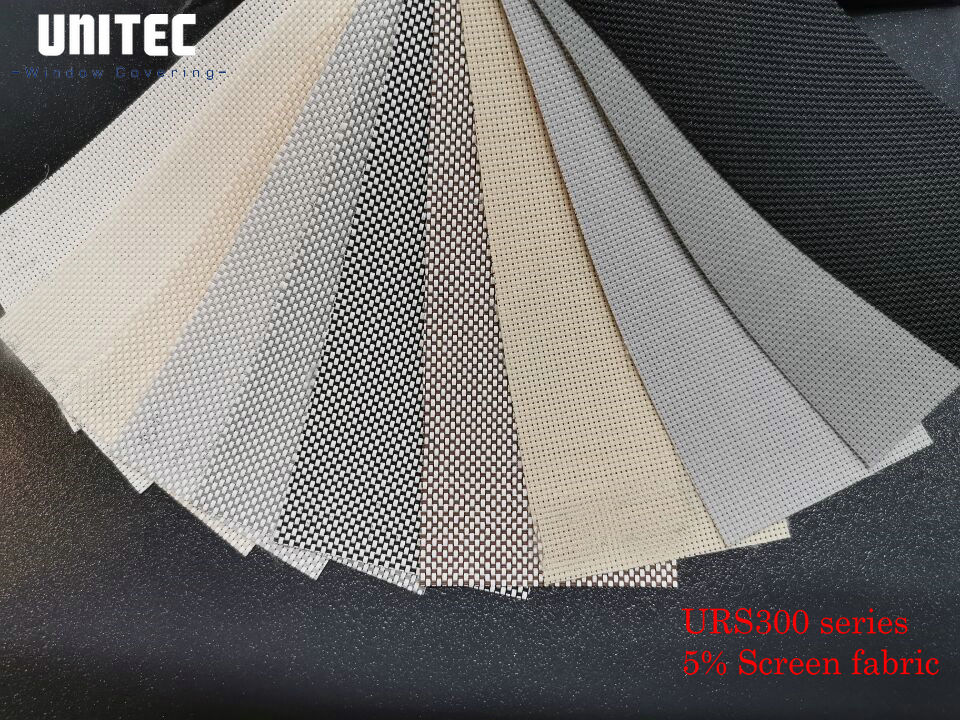

Description of sunscreen roller blinds

The sunscreen fabric is preferably a structure of at least two strips, although it can be made of three strips, four strips, etc., depending on the complexity required for the pattern.

The fabric is preferably configured to have an openness of about 1% to about 10%, especially the screen 5% (defined as the amount of open space relative to the entire fabric area). Those of ordinary skill in the art will easily understand. You can select the degree of opening to adjust the amount of light you want to let through, the amount of obstruction you want, etc. For example, a sunscreen designed to be used on a window on the sun-facing side of a building may be designed to be less open, while the “dark side” of the building is designed to be more open to allow more natural light to enter the room.

Post time: Aug-05-2020